The Perks of Using litho printing for Business Collateral

The Perks of Using litho printing for Business Collateral

Blog Article

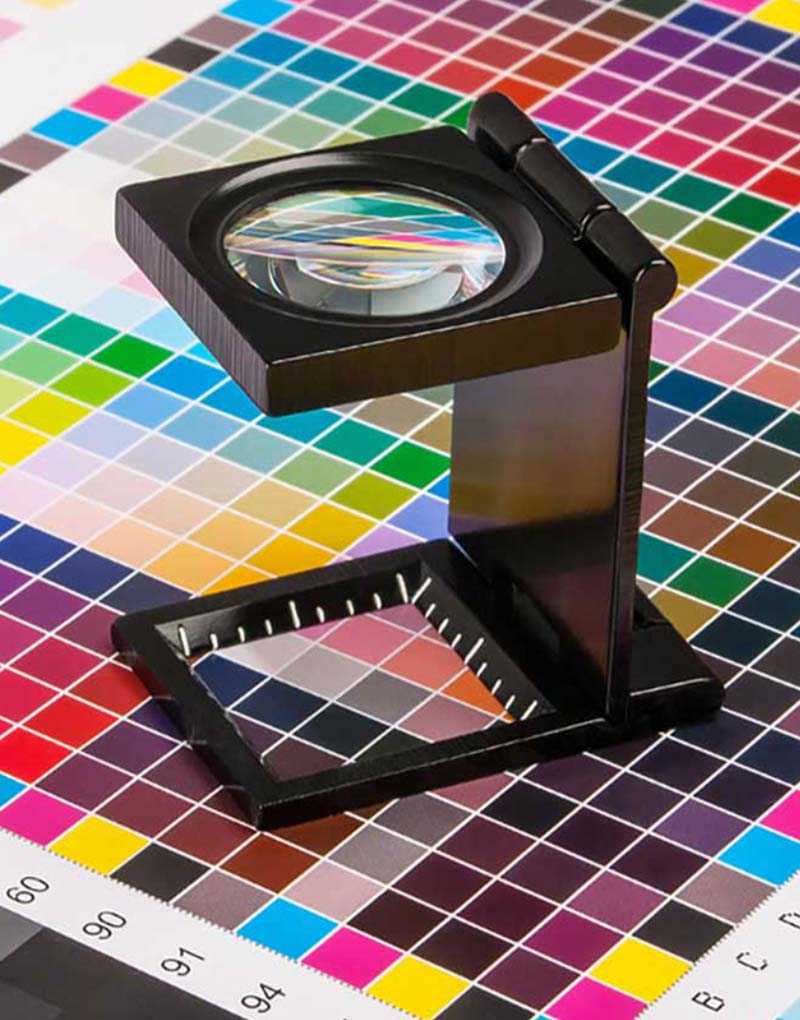

A Comprehensive Guide to Comprehending Litho Printing Methods

The globe of litho printing, a technique originating from the late 18th century, is a fascinating blend of history, science, advancement and art. Keep with us as we journey right into the captivating realm of litho printing.

The Historical Advancement of Litho Printing

The historical trajectory of litho printing, a pivotal development in the world of communication, is an exciting tale of human ingenuity. The process evolved with the development of the rotating press, which considerably boosted performance. Each phase of litho printing's advancement showcases mankind's relentless quest of performance and quality in visual communication.

Decoding the Science Behind Litho Printing Inks

Relocating ahead in the expedition of litho printing techniques, the focus now shifts to the scientific research behind litho printing inks. The composition of these inks, their drying procedure, and shade mixing strategies develop the backbone of this complicated art type. Understanding these components is critical to understanding the craft and achieving the desired print results.

Make-up of Litho Inks

In lithographic printing, the basic function of litho inks can not be overemphasized. Pigments, the color-providing aspects, are carefully ground particles suspended in the lorry, a fluid that lugs the pigment onto the printing surface. Each element plays an important part in the final print's high quality, making the accurate formulation of litho inks a detailed scientific research.

Ink Drying Refine

From the structure of litho inks, interest transforms to the interesting process of ink drying out. Two key approaches are used in litho printing: oxidative drying and absorption. Absorption, on the other hand, includes the ink leaking right into the paper fibers, which is a quicker procedure but can lead to much less lively shades.

Shade Mixing Techniques

While the drying procedure plays an essential duty in litho printing, the science of shade blending techniques holds equal significance. The scientific research behind litho printing inks additionally takes into account the openness of the ink, which influences just how shades overlay and mix.

The Art and Layout Aspects in Litho Printing

Litho printing breathes life right into art and design with its unique components. The procedure entails producing a photo on a lithographic sedimentary rock plate or steel plate with a smooth surface area. The photo is after that printed onto a medium, generally paper, by transferring the ink from the plate. What sets litho printing apart is its ability to replicate complex layouts with high integrity, making the result almost similar to the initial artwork. This is achieved with making use of various line techniques such as hatching, cross-hatching, and stippling, which enable a variety of tonal results. Furthermore, litho printing suits a selection of shades, making it possible for artists to create vivid and dynamic prints. This combination of precision and flexibility makes litho printing a preferred choice for several artists and designers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have actually located extensive usage in the contemporary commercial market. Its impact and importance remain to grow with the introduction of new advancements and modern technologies in the area. This section will certainly check out these contemporary applications and the transformative duty they play in the printing industry.

Commercial Litho Printing Makes Use Of

In today's digital age, one may wonder regarding the relevance of conventional printing techniques. Litho printing remains an important component of the commercial market. High-volume printing tasks, such as the manufacturing of books, newspapers, and packaging, count on litho printing for its ability to deliver exceptional image high quality and expense performance. The process, which includes transferring an inked picture from a plate onto a rubber blanket and then to the printing surface area, provides unequaled uniformity. This makes it suitable for tasks requiring a large print run. Litho printing additionally gives a broad color spectrum, above that of electronic printing. This makes it the best choice for jobs that require lively, premium shade recreation.

Innovations in Litho Printing

Pushing the borders of conventional techniques, contemporary innovations have actually fueled a host of innovations in litho printing. These breakthroughs have not just enhanced the high quality and efficiency of litho prints but also increased its application extent. One famous growth is electronic litho printing, which incorporates the merits of digital innovation with litho's high-quality result. This crossbreed version provides faster configuration times, lowered waste, and makes it possible for on-demand printing. An additional significant improvement is the intro of environmentally pleasant inks. These inks, made from veggie or soy-based remedies, have actually dramatically reduced the sector's environmental impact. litho printing. In addition, the advancement of innovative see page plate technology has streamlined the printing process, resulting in sharper photos and improved color fidelity. These technologies highlight the enduring importance of litho printing in the contemporary world.

Checking out the Process of Litho Printing: Action by Action

Challenges and Solutions in Contemporary Litho Printing

In spite of the accuracy and tradition that litho printing happily promotes, it is not without its set of modern challenges. One of the most prevalent concerns include the high preliminary setup cost, trouble in printing variable information, and environmental problems because of chemical usage. Nonetheless, services are arising as modern technology develops. Digital litho printing permits cost-effective brief runs and very easy customization, resolving the issue of variable information. Environmentally-friendly inks and safer plate-making processes reduce ecological concerns. Additionally, innovations in automation have linked here minimized labor expenses, additionally democratizing the lithography procedure. Therefore, while there are challenges, the litho printing industry is proactively adjusting to satisfy them head-on, guaranteeing its importance in the future.

Conclusion

In conclusion, litho printing, with its abundant background and scientific complexities, holds a considerable place in the print industry. As the guide exposes, it's a synthesis of art and innovation, with modern improvements guaranteeing its relevance. Nonetheless, the sector encounters challenges that call for innovative options, with an i thought about this emphasis on automation and sustainability. The future of litho printing pivots on its capability to adapt to these transforming needs, attesting its enduring worth in a progressing market.

Report this page